Mastering Heat Exchanger Design: A Comprehensive Guide

1. Introduction to Heat Exchangers

Heat exchangers are crucial components in various industries, facilitating efficient energy transfer between two or more fluids at different temperatures. Understanding their design principles is paramount for optimal performance and cost-effectiveness. This comprehensive guide delves into the key aspects of heat exchanger design, covering fundamental concepts, various types, design considerations, and optimization techniques.

- Importance in various industries (power generation, chemical processing, HVAC, etc.)

- Basic principles of heat transfer: conduction, convection, and radiation

- Overview of heat exchanger types and their applications

2. Types of Heat Exchangers

Numerous heat exchanger types exist, each with unique characteristics and applications. The choice depends on factors like fluid properties, temperature differences, pressure drops, and cost constraints.

- Recuperators:

- Parallel flow

- Counterflow

- Crossflow

- Advantages and disadvantages of each configuration

- Regenerators:

- Rotary regenerators

- Fixed matrix regenerators

- Applications and limitations

- Direct Contact Heat Exchangers:

- Gas-liquid contact

- Liquid-liquid contact

- Advantages and disadvantages

- Plate Heat Exchangers:

- Plate configurations and arrangements

- Advantages: high efficiency, compact design, ease of cleaning

- Disadvantages: pressure limitations, susceptibility to fouling

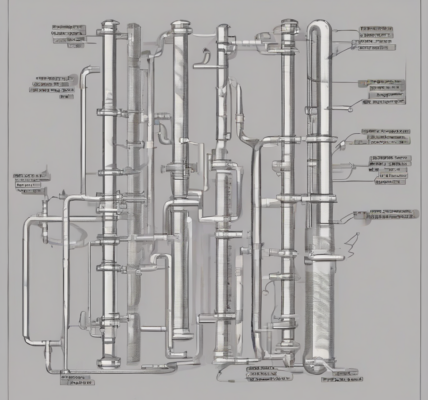

- Shell and Tube Heat Exchangers:

- Different shell and tube arrangements (U-tube, straight tube, etc.)

- Baffe designs and their impact on flow patterns

- Advantages: high pressure capabilities, robustness, wide range of applications

- Disadvantages: large size, difficult cleaning, potential for fouling

3. Design Considerations

Effective heat exchanger design requires careful consideration of various parameters and constraints.

- Heat Transfer Calculations:

- Log mean temperature difference (LMTD) method

- Effectiveness-NTU method

- Applying appropriate correlations for heat transfer coefficients

- Accounting for fouling resistance

- Pressure Drop Calculations:

- Importance of minimizing pressure drop

- Methods for calculating pressure drop in different heat exchanger types

- Impact of pressure drop on pumping power requirements

- Material Selection:

- Corrosion resistance

- Thermal conductivity

- Cost

- Operating temperature and pressure limitations

- Manufacturing and Construction:

- Welding techniques

- Joining methods

- Quality control

- Fouling and Cleaning:

- Types of fouling (scaling, corrosion, biological fouling)

- Methods for fouling mitigation (chemical cleaning, mechanical cleaning)

- Design features for minimizing fouling

4. Optimization Techniques

Optimizing heat exchanger design involves balancing performance, cost, and other relevant factors.

- Numerical Optimization:

- Using optimization algorithms to find optimal design parameters

- Defining objective functions (e.g., minimizing cost, maximizing efficiency)

- Constraint handling

- Genetic Algorithms:

- Evolutionary approach to optimization

- Advantages and disadvantages compared to other methods

- Experimental Design:

- Planning experiments to improve understanding of design parameters

- Statistical analysis of experimental data

- Computational Fluid Dynamics (CFD):

- Simulating flow patterns and heat transfer within the heat exchanger

- Improving design based on CFD simulations

5. Advanced Topics

- Compact Heat Exchangers:

- Design principles and applications

- High surface area-to-volume ratio

- Microchannel Heat Exchangers:

- Miniaturization and enhanced heat transfer

- Challenges in manufacturing and design

- Heat Pipes:

- Two-phase flow heat transfer

- Applications in high heat flux situations

- Thermoacoustic Heat Exchangers:

- Sound-based heat transfer enhancement

- Potential applications and ongoing research

6. Case Studies

Real-world examples illustrating the application of heat exchanger design principles.

- Example 1: Design of a shell and tube heat exchanger for a power plant

- Example 2: Optimization of a plate heat exchanger for a food processing facility

- Example 3: Design of a microchannel heat exchanger for an electronic device